Just

over the fence from the woodland area of Dyke Farm Nature

Reserve lies a large open field, part of the Moffat &

District Community Nature Reserve (MDCNR). At the far side

of this field lies a fenced off area covered in mosses.

It is what is known to the more senior country people as

a 'shaky bog', this implying that it has no firm foundation

and may well be a blanket of mosses lying over water. This

is the Lint Pool indicated on the maps of the MDCNR. Many

people have asked where the name of 'Lint Pool' originates

as it does not immediately appears to be a pool. The only

water to be seen is where a small excavation has been done

in one corner to give a breeding area for aquatic insects.

Just

over the fence from the woodland area of Dyke Farm Nature

Reserve lies a large open field, part of the Moffat &

District Community Nature Reserve (MDCNR). At the far side

of this field lies a fenced off area covered in mosses.

It is what is known to the more senior country people as

a 'shaky bog', this implying that it has no firm foundation

and may well be a blanket of mosses lying over water. This

is the Lint Pool indicated on the maps of the MDCNR. Many

people have asked where the name of 'Lint Pool' originates

as it does not immediately appears to be a pool. The only

water to be seen is where a small excavation has been done

in one corner to give a breeding area for aquatic insects.

A 'Lint Pool'

is a pool of water, often stagnant, in which flax stems

were soaked before removal of the fibres used in the manufacture

of linen. These pools were once common throughout Britain.

Lint probably

gets its name from the Latin 'linteus' - a cloth made from

natural fibre, usually flax. This is found as 'linette'

in Old French and, in Old English, 'linet'.

Before the days

of man-made fibres, flax (with cotton and wool) was a main

source of cloth manufacture and gave us the term 'linen'

we are all familiar with. Flax was grown widely in the area

from Europe across to East Asia - a major industry.

The flax plant

(Linum usitatissimum) is also commonly known as linseed

(derived from 'lint seed) as the seed is used for the production

of linseed oil, although L.flavum, a shorter stemmed variety,

is normally grown for this purpose. Flax requires a rich,

well-cultivated soil and a reasonably temperate climate.

It is sown in spring in a similar manner to oats, wheat

or barley, to produce a long tightly-packed growth some

2½ to 3 feet tall. The flowers form a cluster at

the top usually sky blue (The Wee Blue Blossom) although

some new strains of flax are white. In autumn the flowers

wither and seed balls are formed, harvesting being done

before the seed balls start to open.

Harvesting for

fibre is normally done by uprooting the whole plant to get

the maximum length of fibre. If the seed is not required,

the plants are transferred immediately to the 'retting'

stage otherwise it is first left in the field to dry and

then a simple threshing is undertaken to remove the seed

before 'retting' takes place to obtain the fibre. Seed may

be retained for sowing in the following year or sent off

for the production of linseed oil.

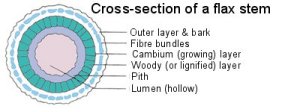

Basically, the

flax plant stem is made up of various layers with the bundles

of fibre near the outside and woody matter on the inside,

all bound together with pectin, which is a natural gummy

substance, and a tough outer skin  or

'straw'. One of the layers contains the fibre that now has

to be extracted from the rest of the stem.

or

'straw'. One of the layers contains the fibre that now has

to be extracted from the rest of the stem.

The woody matter and pith has to be broken down and removed

to release the fibre. This is the 'retting' process and

is nothing more than rotting away the unwanted material.

The plants are bundled and then immersed in water - often

in stagnant or near stagnant ponds - hence the origin of

the name 'lint pool'. This essentially leaves a hollow stem

with the fibre layer enclosed within the outermost skin

layer. The process also breaks down the pectins that bind

the fibres together and softens the fibres. Local knowledge

was needed to know how long to soak the flax, excessive

time would damage the fibres while too short a time would

not give time for the unwanted material to rot away.

After retting.

the next step is to separate the fibres from the remaining

material (straw) that surrounds the fibres. Two methods

were used, either crushing to break the outer sheath or

by scraping (scutching) to remove part of the sheath to

allow easy removal of the rest. The fibres are then exposed.

The last stage

is the 'heckling' where the stalks are passed through a

series of combs or rollers to separate the fibres from the

remaining material. The best fibres are used for spinning

into the threads used for weaving linen cloth while the

coarser ones, perhaps still containing some traces of the

outer straw, are more suited to making ropes, cords or sacking.

Before the advent

of man-made fibres and the popularity of cotton, flax growing

was a major industry. In communities where flax was grown

intensively there was often also a local weaving mill but

mainly the fibres had to travel much further afield.

Over time, the

pools generally became quite acidic, a condition favoured

by many mosses. It is no surprise, that since the pools

became abandoned, that mosses have flourished and completely

covered over the water giving us these 'shaky bogs'. It

would be unwise to try walking on one as it would be likely

that you would break through the moss covering and become

stranded with little hope of escape.

Incidentally,

there is a local rumour that, back in the days when the

pool was in use, a horse and cart slipped inadvertently

into the pool, efforts to recover them were not successful

and their remains are still in there!